- Our Products

Ultra Filtration (UF)

Ultrafiltration (UF) membranes are pressure-driven separation systems with pore sizes typically ranging from 0.01–0.05 microns. They effectively remove suspended solids, bacteria, viruses, and colloids while allowing salts, sugars, and smaller molecules to pass through. UF delivers high clarity and pathogen-free water, making it ideal for pre-treatment in water purification and for hygienic processes in food, beverage, and pharmaceutical industries.

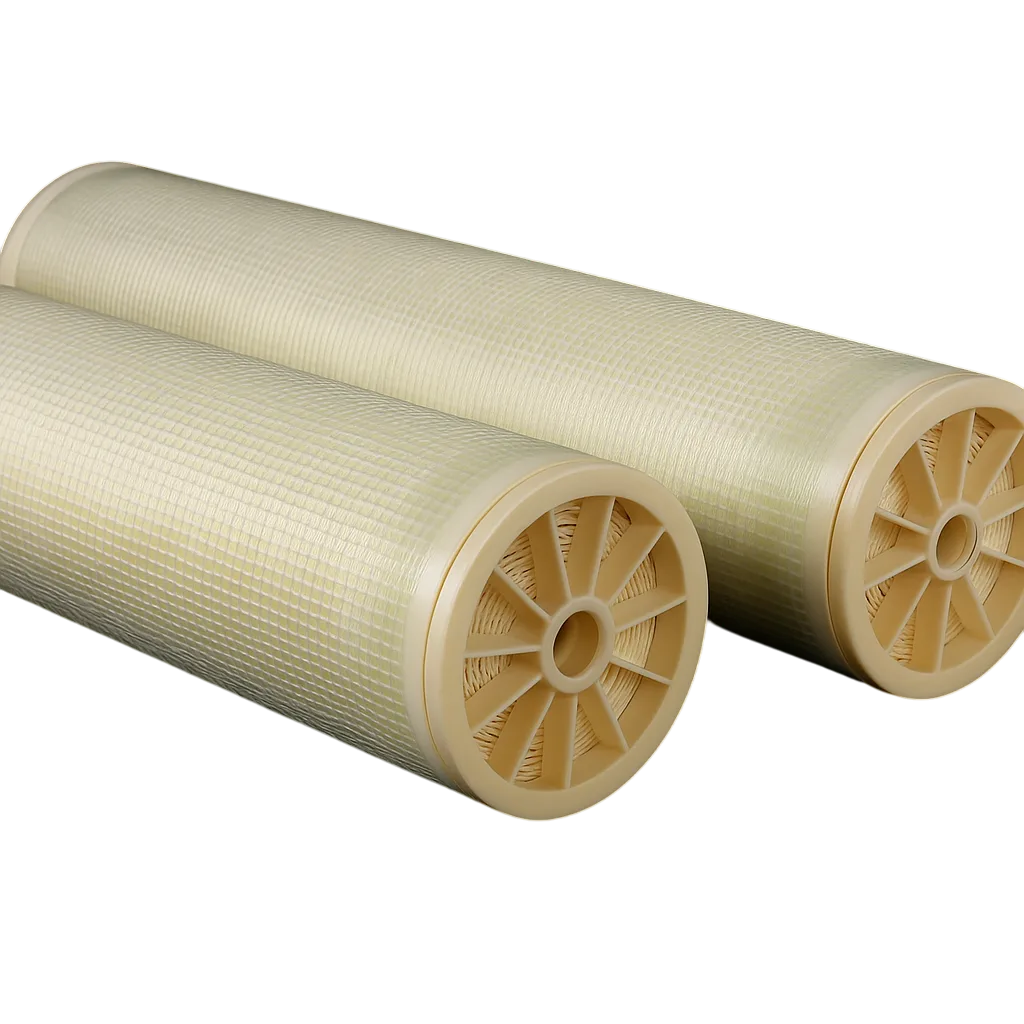

Ultra Filtration - Spiral

Spiral Wound Ultrafiltration (UF) membranes are designed for efficient separation of suspended solids, bacteria, and high-molecular-weight compounds while allowing essential salts and small molecules to pass through. With their compact spiral design, they provide high surface area, stable performance, and easy cleaning (CIP/SIP compatibility), making them well-suited for hygienic applications in water purification, food & beverage processing, and pharmaceutical production.

| Model | Material | MWCO | Size | Feed Spacer | Application |

|---|---|---|---|---|---|

| UFPE05 | PES | 5000 Da | 8040 / 4040 / 4021 | 28, 31, 34, 46 MIL | Protein Concentration, Food Extracts |

| UFPE10 | PES | 10000 Da | 8040 / 4040 / 4021 | Enzyme Concentration, Gelatin Concentration, Protein Concentration | |

| UFPE20 | PES | 20000 Da | 8040 / 4040 / 4021 | Nutraceutical & Fermentation Products, Biotech Separations | |

| UFPE30 | PES | 30000 Da | 8040 / 4040 / 4021 | Separation of Bioactive Peptides from Whey & Milk | |

| UFPE50 | PES | 50000 Da | 8040 / 4040 / 4021 | Juice & Beverages Clarification, Water & Process Treatment | |

| UFPE75 | PES | 75000 Da | 8040 / 4040 / 4021 | Water Purification, Extract Purification | |

| UFPE100 | PES | 100000 Da | 8040 / 4040 / 4021 | Sugar & Sweetener Clarification, Corn Wet Milling |

Key Applications :

Water & Wastewater Treatment – Removal of suspended solids, turbidity, and microorganisms.

Food & Beverage Processing – Clarification of juices, wine, and beer; concentration of proteins and enzymes.

Dairy Industry – Separation and concentration of whey proteins and milk components.

Pharmaceuticals & Biotechnology – Sterile filtration, cell harvesting, and removal of pyrogens.

Chemical Processing – Recovery of valuable compounds and removal of colloids from process streams.

Domestic Membrane Ultra Filtration

Domestic Ultrafiltration (UF) membranes provide reliable water purification by removing bacteria, cysts, colloids, and fine suspended particles while retaining essential minerals. Operating without electricity or chemical additives, domestic UF membranes ensure safe, clean, and great-tasting drinking water, making them an efficient choice for household water purification systems.

| MODAL | MATIRIAL | MWCO | SIZE | APPLICATION |

|---|---|---|---|---|

| UF 2012 – 10 | PES | 10000 Da | 1812/2012/3012 | Enzyme Concentration, Gelatin Concentration, Protein Concentration |

| UF 2012 – 30 | PES | 30000 Da | 1812/2012/3012 | Separation of Bioactive peptides from Whey & Milk |

| UF 2012 – 50 | PES | 50000 Da | 1812/2012/3012 | Juice & Beverages Clarification, Water & Process Treatment |

| UF 2012 – 75 | PES | 75000 Da | 1812/2012/3012 | Water Purification, Extract Purification |

Key Applications :

Drinking Water Purification – Removes bacteria, cysts, and suspended solids for safe household water.

Point-of-Use Water Filters – Commonly used in kitchen filters and countertop systems.

RO System Pre-Filtration – Acts as a protective layer before Reverse Osmosis, extending RO membrane life.

Emergency & Portable Filters – Applied in gravity-based and portable filtration units for areas without electricity.

Community & Rural Water Solutions – Ideal for providing clean water in small-scale, low-pressure systems.

Sanitary Membrane Ultra Filtration

Sanitary Ultrafiltration (UF) membranes are engineered for hygienic processing environments, providing reliable removal of bacteria, viruses, colloids, and suspended solids. With spiral-wound designs optimized for CIP/SIP compatibility, they ensure high purity water and product consistency across dairy, food, beverage, and pharmaceutical applications under strict sanitary standards.

| MODAL | MATIRIAL | MWCO | SIZE | FEED SPACER | APPLICATION |

|---|---|---|---|---|---|

| UFPE05 | PES | 5000 Da | 8040/4040/4021 | 28,31,34,46 MIL | Protein Concentration, Food Extracts |

| UFPE10 | PES | 10000 Da | 8040/4040/4021 | Enzyme Concentration, Gelatin Concentration, Protein Concentration | |

| UFPE20 | PES | 20000 Da | 8040/4040/4021 | Nutraceutical & Fermentation Products, biotech separations | |

| UFPE30 | PES | 30000 Da | 8040/4040/4021 | Separation of Bioactive peptides from Whey & Milk | |

| UFPE50 | PES | 50000 Da | 8040/4040/4021 | Juice & Beverages Clarification, Water & Process Treatment | |

| UFPE75 | PES | 75000 Da | 8040/4040/4021 | Water Purification, Extract Purification | |

| UFPE100 | PES | 100000 Da | 8040/4040/4021 | Sugar & Sweetener Clarification, Corn wet Milling |

Key Applications :

Beverage Clarification – Removal of suspended solids and microorganisms while preserving flavor and nutrients.

Dairy Processing – Concentration and separation of milk proteins, enzymes, and whey under hygienic conditions.

Pharmaceutical Water Treatment – Production of pathogen-free and endotoxin-reduced process water.

Food Processing – Clarification of fruit juices, gelatin, and other liquid foods with high purity requirements.

Biotechnology & Fermentation – Sterile filtration and removal of microorganisms to protect sensitive processes.

Hollow Fiber Membrane Ultra Filtration

Hollow Fiber Ultrafiltration (UF) membranes provide high surface area filtration with pore sizes of 0.01–0.05 microns, effectively removing bacteria, viruses, and suspended solids while maintaining essential minerals. Their compact design, backwash capability, and cost-effectiveness make them ideal for large-scale water purification, municipal treatment, and industrial process applications.

| MODAL | MATERIAL | Flow Direction | Pore Size | Maximum Feed Turbidity | Maximum Permeate Flux | Maximum Feed Pressure | Maximum Back Wash Pressure |

|---|---|---|---|---|---|---|---|

| 4060(4″) | PES | In-to-Out / Out-to-In | 0.03 μm | <50 NTU | 120 L/m²h | 0.5 MPa | 0.25 MPa |

| PVDF | Out-to-In | <100 NTU | 150 L/m²h | ||||

| PAN | In-to-Out | <80 NTU | 120 L/m²h | ||||

| 6060(6″) | PES | In-to-Out / Out-to-In | <50 NTU | 120 L/m²h | |||

| PVDF | Out-to-In | <100 NTU | 150 L/m²h | ||||

| PAN | In-to-Out | <80 NTU | 120 L/m²h | ||||

| 2860(8″) | PES | In-to-Out / Out-to-In | <50 NTU | 120 L/m²h | |||

| PVDF | Out-to-In | <100 NTU | 150 L/m²h | ||||

| PAN | In-to-Out | <80 NTU | 120 L/m²h | ||||

| 2882(8″) | PES | In-to-Out / Out-to-In | <50 NTU | 120 L/m²h | |||

| PVDF | Out-to-In | <100 NTU | 150 L/m²h | ||||

| PAN | In-to-Out | <80 NTU | 120 L/m²h |

Key Applications :

Municipal Drinking Water Treatment – Removal of pathogens, turbidity, and suspended solids.

Industrial Process Water – Pre-treatment for reverse osmosis and other purification systems.

Wastewater Recycling – Clarification and reuse of treated wastewater.

Food & Beverage Industry – Clarification of beverages, removal of impurities while retaining nutrients.

Pharmaceutical & Biotech – Sterile filtration for process water and intermediate solutions.

Osmotech is an ultimate pacesetter of advanced membranes technologies dealing with water purification challenges located at Rajkot-Gujarat-India with highly equipped industrial and infrastructure. Osmotech is committed to provide desalinated solution to the entire lifecycle of purification solution.

Explore

Copyright © 2024 OSMOTECH. All Rights Reserve.